Essential Punch provides the perfect CAM solution if you are planning to utilize your current CAD investment. Its cost effectively provides your operators with the World Class Radan CAM solution they require to reduce lead times and optimize your punch machine tools.

The seamless process delivered by Essential Punch provides an easier to use experience for your operators, whilst accuracy and consistency of programming is maintained with the collation of process critical data in the Manufacturing Database (MDB). Material, tooling and machine tool specific data are stored in the MDB in readiness for instantaneous distribution when required to assist an operator or automated process.

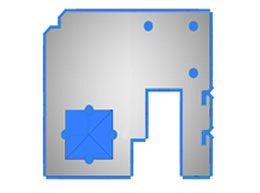

Essential Punch permits multiple tooling setups to be applied to a part for different nesting orientations. This enables the downstream nesting process to fully optimize material utilization by part rotation, which may have otherwize been restricted due to tool rotation limitations. To minimize programming lead time identification and manipulation of tooling is paramount to an operator, Radpunch provides this capability with the user customisable interactive tool list. The easy to use interface enables an operator to quickly identify and interact with tooling at process critical stages.

The power of automation with the ability to control by your preferences. The Essential Punch programming solution provides your operators with easy to use software that can be educated to adopt your preferred practices and processes. If material utilization is critical to your business upgrading the nester to Radnest our true shape nester will raize your material utilization whilst also providing further advanced nesting tools for your operator.

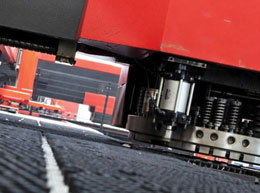

A machine tool is only as efficient as the software driving it, so that is why we personally install every Radan post processor to ensure that it is commissioned to match your machine tool and controller.