Radbend from Radan is the comprehensive offline programming solution for press brakes. Completely integrated with Radan3D it also provides a full 3D simulation of the bending process.

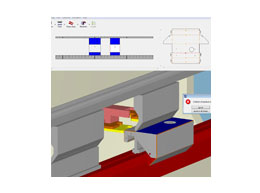

Radbend enables full accurate 3D-model simulation of the bending process, including advanced features such as automatic bend sequence calculation, automatic tool selection and automatic finger stop placement, offering simple programming and high productivity.

The ability to program and verify bending operations offline frees up valuable machine time and improves first-off reliability, reducing manufacturing costs. Radbend also eliminates costly mistakes with automatic detection of collisions with both tooling and the machine tool itself.

Radbend is available to provide offline programming and simulation of a wide variety of press brake machinery. Radbend can create full shop floor documentation in print form or a file for viewing on a shop floor viewer and DNC system ensuring access to only controlled data from production office through to shop floor resulting in a 'right first time' manufacturing approach.

Radbend features high levels of automation. The system examines the part to be programd and automatically determines a bending sequence taking into account part geometry and best machinery practice.

In addition, finger stop positions are set automatically to provide reliable positioning.

Radbend's tooling library can incorporate a tooling manufacturer's complete inventory, enabling nonstandard tools to be tested and proven on new products before purchase.

Radbend is totally press brake independent. Users are able to program all of their press brakes from one common interface. This offers great flexibility where users can quickly try out several press brakes to ensure the right machine for the job.

Radbend can import data in a range of 2D and 3D formats as well as having specific plug-in interfaces for well known 3D CAD systems.

Autodesk Inventor can be fully integrated with Radbend using the plug-in. The Radbend plug- in offers a seamless, accurate and intelligent transfer of data between these two programs.

Taking your part from Autodesk Inventor into Radbend couldn't be more straightforward. Once you are satisfied with your design simply click on the Radbend icon and your part and associated information gets transported into Radbend.

Utilizing the Radbend Plug- in, taking your part from SolidWorks, Standard, Professional or Premium couldn't be more straight forward. Once you are happy with your design simply click on the Radbend icon and your drawing and associated files are seamlessly transferred into Radbend.

Benefits include:

Press brake independent, Radbend can help you to reduce bottlenecks and costs, whilst increasing efficiency and productivity by enabling you to program and verify your bending operations offline as well as detecting any collisions with the tooling, finger stops and the machine tool itself.